The Printed House is Only the Beginning

Last week we ran one of those “oh, come on now!” stories – the idea that a whole house may one day spring from the feedstock of a 3D printer. Strange but true. And not only that, the idea could have implications well beyond the world of architecture. You can’t help but follow up on a story about a printed house, so here we go: are we at the beginning of an additive future?

Each time we hear about advancements in additive manufacturing, it seems a little more tantalizing… and a little crazier. But there have to be limits sooner or later, right? I mean, who would be crazy enough to attempt a 3D printed house?

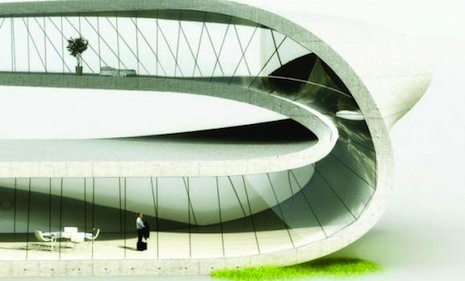

Dutch architect Janjaap Ruijssenaars of Universe Architecture, that’s who. The final project will be a single flowing design resulting in a two story building with a twisted, continuous surface in which the floor eventually becomes the ceiling. Ruijssenaars hopes to begin construction by 2014. He doesn’t have a client or location for the house yet, but the notoriety alone may be enough to deal with those two problems.

Dutch architect Janjaap Ruijssenaars of Universe Architecture, that’s who. The final project will be a single flowing design resulting in a two story building with a twisted, continuous surface in which the floor eventually becomes the ceiling. Ruijssenaars hopes to begin construction by 2014. He doesn’t have a client or location for the house yet, but the notoriety alone may be enough to deal with those two problems.

So how did Ruijssenaars come up with the idea? In 2009, Universe Architecture entered a competition to build on the western coast of Ireland. They thought that a traditional house would compete with the landscape, so the idea was to building something that was like the landscape itself. The result was a plan for a continuous structure that doesn’t have a beginning and doesn’t have an end, like a Möbius strip. They didn’t win the competition but decided to pursue the idea anyway.

Now the design will be part of the Europan competition, which lets architects in over 15 different countries build projects over the course of two years. Europan is a European competition of ideas for designers to give form to a Europe in which young and highly-promising designers can contribute to innovations in the field of spatial design.

Ruijssenaars is working with Italian inventor Enrico Dini, creator of the D-Shape 3D printer. The machine uses ground-up rock or sand as feedstock, hardened by a resin-like binding agent. According to D-Shape’s website, the machine “enables full-size sandstone buildings to be made without human intervention.”

Working with Dini, the team at Universe has developed a way to accomplish this goal. They are not going to be printing the whole floor or ceiling as one gigantic piece; rather, they’ll print out 6×9 chunks of frame that will make up the outside shape of the floor or ceiling, resulting in a hollow structure. They then plan on putting in reinforced concrete and assembling the pieces. No word – at least, not yet – on how amenities like plumbing and electric will be integrated, but given the audacity of the idea, such practicalities seem almost as trivial as the fact that there’s no location or buyer.

The Dutch seem to have proficiency for unique automation. Not long ago we heard about the Tiger-Stone, another invention from the Netherlands that prints out brick and cobblestone roads. While not precisely additive manufacturing, it certainly implies the future of whole-construction automation, in which entire whatevers are built from feedstock with minimal human intervention.

The Dutch seem to have proficiency for unique automation. Not long ago we heard about the Tiger-Stone, another invention from the Netherlands that prints out brick and cobblestone roads. While not precisely additive manufacturing, it certainly implies the future of whole-construction automation, in which entire whatevers are built from feedstock with minimal human intervention.

The full promise of additive manufacturing is still a long way off, and it’s certainly possible that ongoing R&D may demonstrate that ambitious 3D printing projects for houses and roads just aren’t the best use of the technology. But numerous long-term R&D activities, including those managed by NCMS, have already proven that the foundation of 3D printing is strong for plenty of applications, including complex geometries, medical devices, rapid prototyping and much more. 3D printing has been around in one form or another for a fair length of time, and visionaries are doing ambitious things with it even as the technology is still being proven out.

Architects Unleashed

Back at Universe Architecture, Ruijssenaars notes that 3D printed houses could allow architects direct and complete influence over their designs, without “intermediaries who can add interpretation and realization mistakes.” While those intermediaries might find offense in the remark, there is a kernel of value in it: once a design is proven, every single execution of it would be exactly the same. No chance of a construction company using substandard materials, no chance of corner-cutting, none of the unexpected variances that always seem to occur when you try to do something to your house, only to find that somebody along the line did something weird to it first and it’s going to cost more money to circumvent it.

The natural curves and lines of most 3D printed objects tend to be more in concert with nature, too, unlike traditional, angular structures. Ruijssenaars’ “Landscape House” was intentionally designed to blend in with the slopes and arcs of its surroundings; something that additive manufacturing tends to do naturally anyway: building up from nothing rather than cutting away as traditional machining methods do.

One can certainly imagine an idealized future in which you don’t go shopping for a house, you simply select from a set of predesigned frames (or design your own, if you’re adventurous), choose various packages and amenities, and hit “Print.” All those manufactured houses we tend to get stuck behind on the expressway could multiply quite a bit in the future, though for now even the Landscape House is a dream that has yet to find physical form.

One can certainly imagine an idealized future in which you don’t go shopping for a house, you simply select from a set of predesigned frames (or design your own, if you’re adventurous), choose various packages and amenities, and hit “Print.” All those manufactured houses we tend to get stuck behind on the expressway could multiply quite a bit in the future, though for now even the Landscape House is a dream that has yet to find physical form.