A Brief History of 3D Printing

As we witness the rise of 3D printing, one particular application has proven exceptionally useful: metal printing. Most recently, we reported on NASA's selective metal melting (SLM) method for manufacturing complex rocket engine components, helping to unlock the doors to a future of interstellar travel.

But in order to appreciate the promise of 3D metal printing, we must consider the significant bounds made in 3D printing in the past year alone, as it represents one of the fastest growing technologies today.

Despite numerous recent innovations, metal printing can trace its origins back to the 1880s, when welders used carbon electrode arcs to lay down metal beads. Since then we've developed electron beams and vacuum chambers, but the most important breakthrough has arguably been the laser.

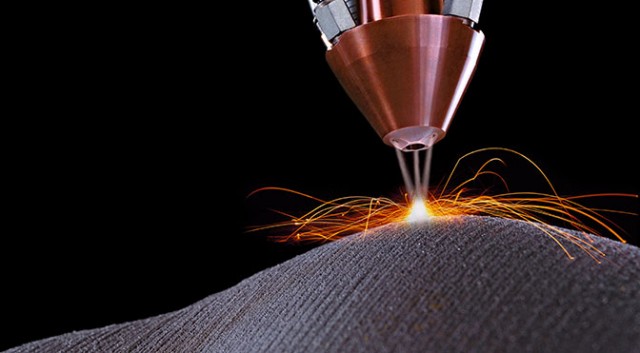

The first laser replaced the oxygen-acetylene torch for welding powdered metal, transforming a relatively crude technique for motor shaft reinforcement into a powerful and precise construction tool. Laser metal deposition welding is accomplished with a device that pipes a laser down through central bore that merges with a powdered metal feedstream at the device's tip. The laser then fuses the metal to the target surface. The process is illustrated in the following video, courtesy of Trumpf, the maker of one such device.

;

But the fastest metal printing process far and away is the deposition of a powder matrix containing binders. The binders melt to temporarily hold the metal powder before it is fused in a specialized oven.

One company that has jumped on the potential of this manufacturing process is Shapeways, which has allowed customers to implement custom designs, such as smartphone cases, at a relatively low cost. The only drawback is the weak magnetism of the stainless steel used by their process, which could be enough to damage certain electronics but not strong enough to offer additional utility. But if the direction of the additive manufacturing industry is any indicator, this roadblock too shall pass.

And what about the future? Two technologies could enable the production even higher resolution parts. Two-photon laser curing can pass through a material without reaction until it reaches a specially designed binder. Similarly, the femtosecond laser is transitioning from micromachining and corrective eye surgery to the additive manufacturing world, held back only by the expense of its sapphire crystal core.

But if we manage to 3D print the sapphire in question? Well, that could change everything.

Full story at ExtremeTech