Reshoring: A Path to Sustainable Manufacturing in America

The concept of sustainability is still a subject of many debates, including the debate over whether or not to define and adopt it in all the fields of human activity, including manufacturing. I strongly support the idea that it is necessary and imperative that we agree on what sustainability is and start practicing it. For sustainable manufacturing, I offer the following definition: a business practice of the industrial sector, which expands all the company’s processes and decisions into the social and natural environments it operates in and affects, with the explicit objective of having a neutral or positive impact, while pursuing the desired level of technological and economic performance.

The concept of sustainability is still a subject of many debates, including the debate over whether or not to define and adopt it in all the fields of human activity, including manufacturing. I strongly support the idea that it is necessary and imperative that we agree on what sustainability is and start practicing it. For sustainable manufacturing, I offer the following definition: a business practice of the industrial sector, which expands all the company’s processes and decisions into the social and natural environments it operates in and affects, with the explicit objective of having a neutral or positive impact, while pursuing the desired level of technological and economic performance.

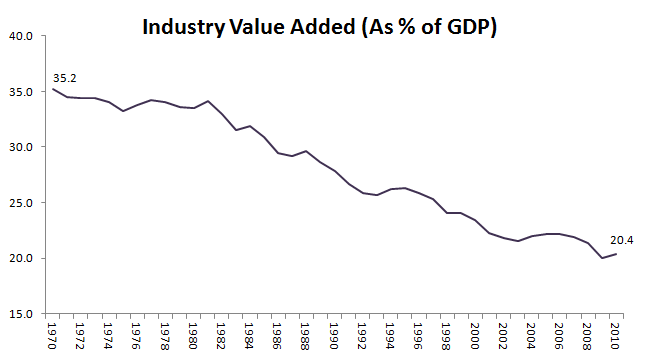

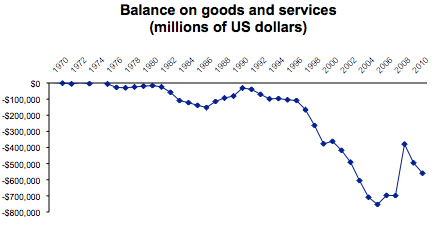

Reshoring manufacturing in the US is a trend that is gathering strength and support from business people, manufacturing professionals, citizens, politicians and even some economists. Ironically, the consultancies, which for decades have undermined US manufacturing, are now beginning to promote reshoring, as the great recession in US has exposed the failure of the so-called post-industrial economic model. The weighting of the US economy, which began in the 1970s (see charts below), from manufacturing to services, especially financial services, from production of goods to consumption of goods and debt has led to the current crisis, the “stickiness” of unemployment and underemployment, wage stagnation and manufacturing de-skilling. Reshoring manufacturing will fix that, while putting US economy and society on a path to sustainability.

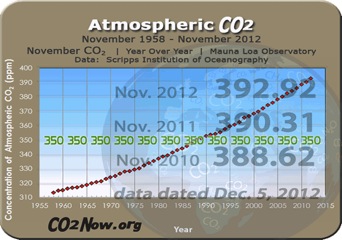

Concurrent with the deterioration of manufacturing in the US and the use labor costs arbitrage in pursuit of short-term shareholder value, another trend has gathered strength: anthropocentric global warming and its negative impact on climate change.

How are they related? I would argue that they are related through the length, complexity and poor control of supply chains, transportation means and routes, the localization of manufacturing in places where, due to their stage of development, quality, environmental and labor standards are not at the highest level. This latter trend reflects and measures the economic externalities of the post-industrial model, or rather de-industrialization model of the developed countries and the US, in particular. In other words, the claim of lower costs and prices brought about by globalization is false, when all costs, internal and external are calculated.

There are many organizations and people making the convincing case for reshoring, among them the Reshoring Initiative led by Harry Moser, which uses the Total Cost of Ownership (TCO) tool. The tool includes both external and internal costs to business, providing a realistic comparison between US and “low-cost” off-shore manufacturing.

Sustainable manufacturing, like sustainability in general, is concerned with all three dimensions of human life: economic, social and natural. Here is a list of some of the expected positive impacts on these dimensions, as reshoring US manufacturing becomes the new normal:

Economic

- High employment at fair, optimal wages

- Restore a real-assets based economy and create a clean, carbon-neutral future economy

- Stable, more reliable planning for the long-term

- Balanced, fair and clean (no embedded carbon) trade

- Replacement of old, non-renewable sources of energy, generation and distribution methods with renewable, clean, highly-efficient, cheaper ones

- Reduced or zero waste of resources, human and material

Social

- Optimal, sustainable living standards for all

- The utilization and constant improvement of all skill levels or collars: blue, white, green

- Restoring science and technology as the foundation of an advanced economy and society

- Quality education at all levels from vocational to academic

- Access to and funding of culture for all citizens

- Stable, flourishing communities with a richness of offering for work and leisure

- Stimulate and use the creativity, manual and intellectual abilities of all citizens

Natural

- Bring the CO2 concentration level down to the 350 ppm target to prevent climate change to reach a level which threatens modern civilization

- Reduce the use of scarce or polluting natural resources through smaller networks of production and distribution

- Integrate manufacturing and other types of business in eco-industrial parks, symbiotic with the surrounding natural environment

Support for reshoring is not a call to end globalization or protect the US domestic market. I view globalization as the means of raising the living standards for all human beings, allowing them to fulfill their potential in a fair and rewarding way. Globalization should not be reduced to free-trade in goods and financial capital.

In regards to trade, I suggest that the only sustainable trade is one in ideas, knowledge, education, and innovation (goods with no mass!) and not in material goods, as it is structured today. Material goods would be best produced in the market of usage. How should that market be defined? By sustainable manufacturing criteria.

Silvia Leahu-Aluas is Principal/Owner of Sustainable Manufacturing Consulting, offering her expertise to manufacturing companies interested in creating and maintaining a sustainable business. She has over 25 years of experience in process engineering, sustainable manufacturing, sales and operations planning, strategic planning, market intelligence, change management, risk management. She holds an MS degree in Mechanical Engineering, major Manufacturing, from the Technical University of Cluj, Romania and an MBA degree, major International Management, from the Indiana University – Bloomington. http://sustainablemanufacturing.biz/

Silvia Leahu-Aluas is Principal/Owner of Sustainable Manufacturing Consulting, offering her expertise to manufacturing companies interested in creating and maintaining a sustainable business. She has over 25 years of experience in process engineering, sustainable manufacturing, sales and operations planning, strategic planning, market intelligence, change management, risk management. She holds an MS degree in Mechanical Engineering, major Manufacturing, from the Technical University of Cluj, Romania and an MBA degree, major International Management, from the Indiana University – Bloomington. http://sustainablemanufacturing.biz/