Ultra-thin Cooling Jets for Next-gen Electronics

Just when you think technology has hit a wall in its ability to scale downward in size, another breakthrough surfaces, and our cell phones and tablets shrink yet again. But this time, it's not because of Moore's Law. Instead, this innovation comes in the form of ultra-thin cooling jets, recently unveiled by GE Global Research.

According to GE researchers, the technology, called Dual Piezoelectric Cooling Jets (DCJ), can dissipate heat at ten times the rate of natural air circulation, and take up significantly less space than traditional cooling fans.

According to GE researchers, the technology, called Dual Piezoelectric Cooling Jets (DCJ), can dissipate heat at ten times the rate of natural air circulation, and take up significantly less space than traditional cooling fans.

According to Peter de Bock, lead electronics engineer at GE Global Research, DCJ is now the optimal cooling solution for ultra-thin consumer electronics. “It's very low power, very simple, and a unique solution for very thin laptops, ultrabooks and the next generation of more powerful tablets.”

But how does it work?

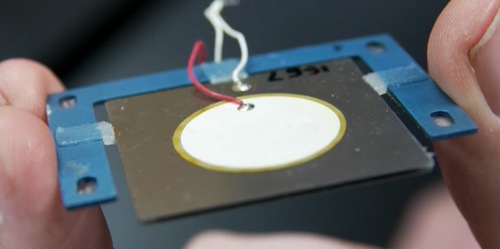

The DCJs feature two ceramic plates that, when supplied with electricity, expand and contract, creating high-velocity airflow. Nearby heated components can then rapidly dissipate heat, just as they would with traditional fans.

This technology is significant, however, because the ceramic plates measure just one millimeter tall, while the entire cooling assembly is a mere 4 millimeters tall – 50 percent smaller than current cooling units.

On top of that, the DCJ uses 50 percent less power than fans, is nearly silent and uses no rotating parts that require maintenance and are prone to breakage.

“[The] DCJ technology not only frees up precious space for system designers, but it consumes significantly less power, allowing as much as 30 minutes of extra battery life,” says Chris Giovanniello, vice president of microelectronics and thermal business development at GE Licensing.

Not only could this technology mean slimmer personal electronics, it also may enable longer battery life and quieter machines, which, thanks to their simplicity, will cost less.

Currently, GE produces the prototypes at a rate of 20 per month. But the technology has now been licensed to Japan's Fujikura LTD for manufacturing, with the high-volume production slated for 2013. It could be inside our cell phones and tablets as early as 2014.

Full story at Txchnologist