Autodesk $21.7 Million Gift to Penn State Behrend Provides Access to Animation and Modeling Software

Investing in education is a time-honored tradition among high technology companies like Cisco, Google, HP, Intel, IBM, Microsoft, Oracle, Texas Instruments and others. Recently, in the field of advanced digital modeling and simulation, a gift on the part of Autodesk Software stands out. It directly addresses some of the more intractable problems facing the “missing middle,” those small to medium sized manufacturers (SMMs) who would like to embrace advanced manufacturing technology like 3D CAD and Computer Aided Engineering (CAE) but have neither the money, in-house infrastructure, or internal talent to do so.

Investing in education is a time-honored tradition among high technology companies like Cisco, Google, HP, Intel, IBM, Microsoft, Oracle, Texas Instruments and others. Recently, in the field of advanced digital modeling and simulation, a gift on the part of Autodesk Software stands out. It directly addresses some of the more intractable problems facing the “missing middle,” those small to medium sized manufacturers (SMMs) who would like to embrace advanced manufacturing technology like 3D CAD and Computer Aided Engineering (CAE) but have neither the money, in-house infrastructure, or internal talent to do so.

The $21.7 million gift to Penn State Erie, The Behrend College will provide its students with access to Autodesk modeling and animation software. This is the largest donation ever received by Penn State Behrend. Specifically the gift allows students to work with three of Autodesk’s key software suites:

• Education Master Suite, which includes 3D CAD and engineering analysis tools

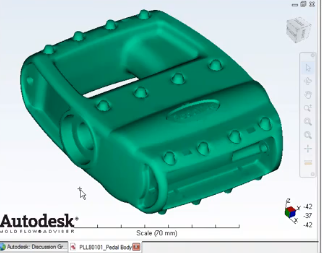

• Simulation Moldflow, an injection molding simulation software that lets manufacturers optimize the design of plastic parts and injection molds, and study the injection molding process

• Entertainment Creation Suite, a set of creative tools used by artists in game development, visual effects and 3D animation. The suite was used to animate the last 17 films that won the Academy Award for best visual effects.

Faculty members in the college’s School of Engineering and professors in chemistry, psychology, game design, and management information systems are already using the software. Every faculty member and student at Penn State Behrend has access to it. Now they can use it for free.

Help for the Missing Middle

Accessibility to Moldflow by students and faculty is a good example of how a gift of technology can provide benefits not only for students and the school, but also for missing middle SMMs.

The relationship with Penn State actually started when Autodesk acquired the Moldflow Corporation in 2008. A number of the Moldflow applications engineers who had made the transition to Autodesk proved to be outstanding performers. When their new supervisors looked into why they were so good at what they did and knew plastics so well, they found the common denominator was that all the engineers had gone through the plastics program at Penn State. This initiated a close relationship between the university and Autodesk, which culminated in the $21.7 gift. In addition to the gift of the various software suites, Penn State teachers also have access to the curriculum that Autodesk has developed for these particular classes.

The relationship with Penn State actually started when Autodesk acquired the Moldflow Corporation in 2008. A number of the Moldflow applications engineers who had made the transition to Autodesk proved to be outstanding performers. When their new supervisors looked into why they were so good at what they did and knew plastics so well, they found the common denominator was that all the engineers had gone through the plastics program at Penn State. This initiated a close relationship between the university and Autodesk, which culminated in the $21.7 gift. In addition to the gift of the various software suites, Penn State teachers also have access to the curriculum that Autodesk has developed for these particular classes.

The students use the software in the College’s state of the art plastics lab to design and evaluate new parts. However, a good part of their educational experience is to work with a number of small to medium sized plastic component manufacturers to redesign existing tools. The SMMs might want to optimize the design of older tools, or modify the design of the tool to get more throughput or decrease defects. For example, they may change injection pressures to eliminate weld lines, change gate locations to bypass those lines, or design the part to be thick enough so that the mold cavity can be filled using only one gate (multiple gates can cause weakness at the weld lines).

Seamless Transition from School to Work

Among the characteristics of a missing middle company that wants to use advanced modeling and simulation in its operations is a shortage of capital to invest in the necessary hardware and software, as well as a lack of internal expertise in such esoteric disciplines as computational fluid dynamics and finite element analysis, and the internal IT infrastructure to support these activities. The Penn State Behrend program directly addresses these problems.

Many of the students in their senior year involved in “capstone” projects working with an outside plastic company, find themselves with a job offer waiting for them upon graduation.

Thus the talent needed by the SMM arrives in the form of a well-trained college graduate turned employee who brings a wealth of knowledge about Moldflow and other CAD software to the company as well as direct experience designing the company’s products.

Says Ralph Ford, director of the School of Engineering, “Graduates of Penn State Behrend and its School of Engineering have enjoyed a rich employment track record, and with access to this software, they will be even better positioned for success.”

For the SMMs, the capital requirements for the high performance computing capabilities needed to run this software is addressed by Autodesk’s cloud computing offering. As we reported in an earlier article, last year the company acquired Blue Ridge Numeric’s and their 20 years of experience creating CFD tools. This software joined Moldflow, Autodesk Inventor, and Autodesk Algor Simulation in a simulation portfolio that is now available in the cloud on a unique pay-as-you go model.

Traditional simulation software can run anywhere from twenty thousand dollars up to hundreds of thousands for just the base package. By being able to access the software in the cloud, the SMMs are spared the upfront costs of deploying a high performance computing infrastructure and the people to run it. Instead, a relatively modest workstation can run the CAD software using resources available in the cloud. And the price is a fraction of the cost of a conventional package purchased under license.

It is this combination of an influx of new talent already familiar with running the SMM’s jobs on Moldflow, and the low cost and accessibility of the Autodesk simulation software in the cloud that adds another dimension to the quest to bring advanced digital manufacturing techniques to the missing middle.