Help Rebecca Fix Her Vette

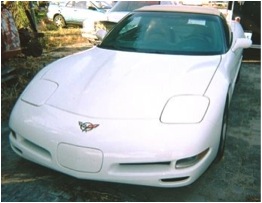

As an owner of a not-quite-vintage, but too-old-for-OEMs-to-care about Corvette, I recently found myself wondering if digital manufacturing could come to my rescue.

But let me start at the beginning.

It’s a 1994 Corvette Convertible with over 100,000 miles on it. It is a lot of fun to drive, particularly when the weather cooperates. And it certainly makes going to work and running errands a little more enjoyable. But the 17 year old car has started to create more problems than joy. I recently discovered that the tray that secures the engine computer had broken. It wasn’t a highly technical or complicated part; in fact it was little more than a metal alloy shelf. Maybe its simplicity is why OEMs no longer stock it, nor do many of the aftermarket parts distributers like Ecklers and Corvette America. The repair garage ordered the part, and it came in damaged. When they tried to get a replacement they found that there were no others in stock!

No problem, I thought. This is the internet age; certainly I can find an engine computer tray from lesser known suppliers or on-line junk yards, right?

No problem, I thought. This is the internet age; certainly I can find an engine computer tray from lesser known suppliers or on-line junk yards, right?

Well, actually, no. After many fruitless searches I find myself empty handed. I did find someone who would machine the part for me in chrome, but at an exorbitant cost, and even then, no assurances it would actually work. Chrome isn’t the right material for the part, sitting next to the engine and above the battery. However, I didn’t relish spending endless weekends at swap meets, searching for the part. But seeing my Corvette parked on a beautiful sunny 70 degree day for lack of a simple metal tray was too much to bear.

I was at the point of purchasing a milling machine for my back yard and grinding the tray myself when I thought, “Hey, I work for NCMS, the leader in digital manufacturing. Certainly this new approach to production can help me.” I mean, after all, Jay Leno has a 3-D printer in his garage to help keep his large collection of old cars on the road, making the parts he needs on demand. Okay, okay - his mechanic probably does it, not him. But I don’t have an extra $10,000 to buy such a machine or even more to have a mechanic at my disposal. Still, the technology is out there to digitally scan the part and recreate it, exactly.

So my next goal was to find someone on-line that is doing this – crafting parts for folks like me on their 3-D printer, replacing parts on demand. Seems logical, right? But so far I have not had any luck.

There are great websites like MakerBot, Instructables (recently bought by Autodesk) and Thingiverse that lets people share 3D designs and shows some of the things made by digital printing, but they are not really set up to address my kind of problem.

So, DM Report readers – any ideas? Do you know anyone that is providing this as a service or someone that will take pity on me and help me digitally make this part?

After all, convertible weather will be here again before we know it.