SGI Expands CFD Capability with OpenCFD Acquisition

SGI acquisition of OpenCFD makes computational fluid dynamics more accessible to SMMs

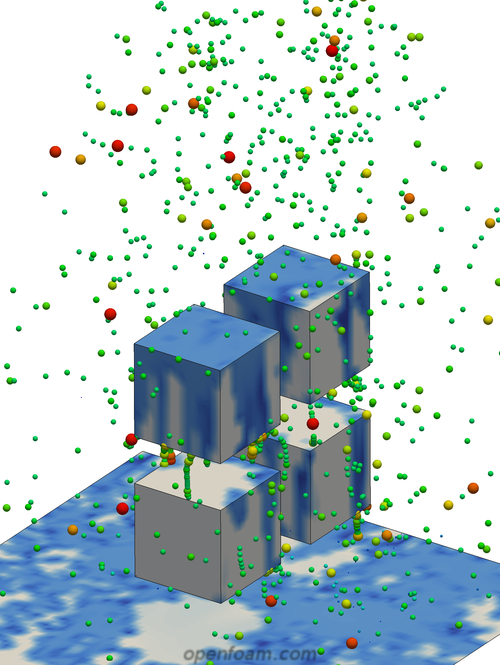

Last month SGI acquired OpenCFD, the developer of OpenFOAM, a robust and widely-used open source CFD software package consisting of 80 solver and 170 utility applications.

In a press release announcing the acquisition, SGI CEO Mark Barrenechea said, "With the acquisition of OpenCFD Ltd., SGI will be able to provide our customers the market's first fully integrated CFD solution, where all the hardware and software work together."

OpenFOAM will continue to be offered free to the business, government and academic communities under the GNU General Public License.

What's in it for Smaller Manufacturers?

Sounds good. But will this move make the benefits of CFD more available to small- to medium-sized manufacturers (SMMs)? Even though the price is right, the software is notoriously complex and requires skill sets and powerful multicore computer systems that many smaller organizations lack.

To find out, we talked with Henry Weller, founder of OpenCFD and now a director of engineering at SGI, and Christian Tanasescu, SGI's vice president of software engineering. Weller, based in London, will continue to oversee the development of OpenFOAM, which includes the newly formed OpenFOAM Foundation.

To find out, we talked with Henry Weller, founder of OpenCFD and now a director of engineering at SGI, and Christian Tanasescu, SGI's vice president of software engineering. Weller, based in London, will continue to oversee the development of OpenFOAM, which includes the newly formed OpenFOAM Foundation.

Tanasescu points out that SGI has a long history in manufacturing as one of the sector's strongest suppliers. In addition to CFD, the company provides workflow solutions in computational electromagnetics, computational structural mechanics, and multidisciplinary simulations. Support is provided for such popular software such as FLUENT, NASTRAN and LS-DYNA.

But currently, CFD is the rising star. "At SGI, we believe that CFD is one of the segments with the highest growth rates in the industry — about 16 to 17 percent a year," says Tanasescu.

Out in Front

Since its inception in the late 1980s at Imperial College, London, OpenFOAM has scored a number of firsts. According to the Wikipedia entry, it is one of the first major packages written in C++, a sharp break with FORTRAN, which had been the de facto standard. It makes full use of C++'s object orientation capabilities and operator overloading to create a human-readable syntax for tensor operations and partial differential equations. But Henry Weller points out that perhaps its single major accomplishment is that OpenFOAM is the first and best general purpose CFD package to be released under an open-source license.

Since its inception in the late 1980s at Imperial College, London, OpenFOAM has scored a number of firsts. According to the Wikipedia entry, it is one of the first major packages written in C++, a sharp break with FORTRAN, which had been the de facto standard. It makes full use of C++'s object orientation capabilities and operator overloading to create a human-readable syntax for tensor operations and partial differential equations. But Henry Weller points out that perhaps its single major accomplishment is that OpenFOAM is the first and best general purpose CFD package to be released under an open-source license.

Weller says that the SGI acquisition has not changed OpenFOAM's open source status or its development going forward. In fact, the entire OpenCFD team has joined SGI as full-time employees based at the company's EMEA headquarters in London.

Last month, SGI also formed the OpenFOAM Foundation to: make sure the software is accessible to anyone who wants it; distribute current and future releases of OpenFOAM under the GNU GPL; and incorporate contributions from the CFD community. Also available through the foundation is an OpenFOAM/SGI package that provides full support including helping customers compile and install the software on their system. Patches and bug reports are also part of the package.

"There's a lot of room for growth," Weller says. "OpenFOAM is very strong in Europe and now we're extending our reach to Asia and the United States. The early adopters were mostly in Germany, France, Scandinavia, France and the UK, but now the most rapid growth is in the U.S. and Japan.

"We get something like 30,000 downloads of each release worldwide, but because no registration is required, we really don't know who most of those users are," he continues. "We do know it's quite a mix, ranging from a retired engineer from Boeing who just enjoys working with the code to large automotive and chemical engineering organizations using OpenFOAM for major support and development contracts. Lots of universities and academics are also using the code — obviously the software's free and open status is a big benefit to this customer segment."

Weller says that OpenFOAM's major differentiator when compared to other commercially available CFD packages is its open source status. "We are happy to have people study the code's details and verify that it does what we say it can do," he comments. For example, the safety-conscious nuclear industry is very committed to studying and testing the code base to verify every aspect of its operation. In addition, the open source approach allows researchers and students to analyze the code and make changes to their OpenFOAM download as they see fit. They can also release those changes to the broader community under the terms of the GPL.

"We don't open the source base to push contributions," explains Weller. "The code base is now about a million lines, so if you allowed just anyone from the public to contribute what they want, OpenFOAM would quickly fall apart. We welcome changes and additions to the code — that's the beauty of open source. But because the software is very tightly integrated, we carefully control and test any modifications and additions before incorporating them in order to guarantee a reliable base."

Helping the SMMs

In addition to large companies, an enthusiastic set of users has coalesced around small and medium sized manufacturers (SMMs) that make up part of the large automotive manufacturers' supply chain. For example, several OpenFOAM users manufacturing fuel injectors are using CFD to understand the behavior of fluid as it moves through hydraulic components. Others are modeling the flow of gases in automobile exhaust systems.

With SGI's backing and the creation of the OpenFOAM Foundation, OpenFOAM has morphed into a hybrid offering: free access to the software combined with a paid support model. Says Weller, "We want to offer more than something that is cheap and open. Our philosophy is that we give away what we have done and only charge for what people need from us. When these smaller manufacturers require help, we can provide the proper level of support tailored to fit their situation — if they need training, onsite help, or assistance setting up the code for a specific job, we supply it on a fee basis."

But Weller cautions that using OpenFOAM is not for the casual user. True, his operation is constantly striving to make the code easier to work with, but users must have a firm understanding of the problem they are addressing — for example, the basic mechanics and physical constraints involved with setting up boundary conditions including inflows and outflows.

This, he says, is a matter of scale. An easy problem is calculating the airflow and subsequent drag around a car — engineers who have attended an OpenFOAM training course can handle this kind of modeling and simulation right away. But suppose, moving over to another field of endeavor, you want to simulate hemoglobin separation in blood using a magnetic fields and centrifugal forces? That, says Weller, is very hard. In this case, you contact the OpenFOAM team, which will work out how set up the simulation to ensure accurate results. But even better, the team will prepare a demo tape for your reference and teach you how to handle this and similar difficult calculations in the future — technology transfer is part of the package.

Breaking Down the Barriers

According to Tanasescu, to be more competitive in today's marketplace, the SMMs must move beyond the barriers preventing them from using modeling and simulation in their product design process.

"There are two primary situations involved," he says. "One is budget; the other is expertise. Today's software is four to five times more expensive than hardware on a per node basis. With OpenFOAM we remove the cost barrier for the software. But the cost of buying hardware for a large or mid-size cluster can't be ignored. That's why at SGI we offer OpenFOAM in the cloud — you only pay for the cycles you use, turning what was a capital expense into an operating expense.

"Our professional services address the other issue — the need for expertise," he adds. "Not only do we provide expert support through our professional services, but also help our customers build their own in-house expertise over time through extensive training. So, for the SMMs, our offering is really complete — we provide the hardware, software, training, and professional services needed to allow smaller manufacturers to be more competitive using the tools of visual prototyping and simulation."