Solar Sintering in the Sahara Desert

Truly it is written, "Mad dogs and Englishmen go out in the midday sun."

Markus Kayser is not a mad dog, but he is an Englishman. And the midday sun he chooses to go out in is about as bright and hot as you can get — it shines on the Sahara desert.

Kayser is a masters candidate in design products at the Royal College of Art in London. He has a particular affinity for the 3D printing process known as sintering.

Last year in August (what better time to visit the desert), he took his first solar machine, a kludgey, low-tech laser cutter that used sun power to fashion a variety of thin 2D plywood components. But more importantly, he realized that the desert provided almost unlimited quantities of two elements fundamental for manufacturing: energy in the form of boundless sunshine; and raw materials — in this case in the form of silica sand made primarily of quartz, stretching away as far as the eye could see.

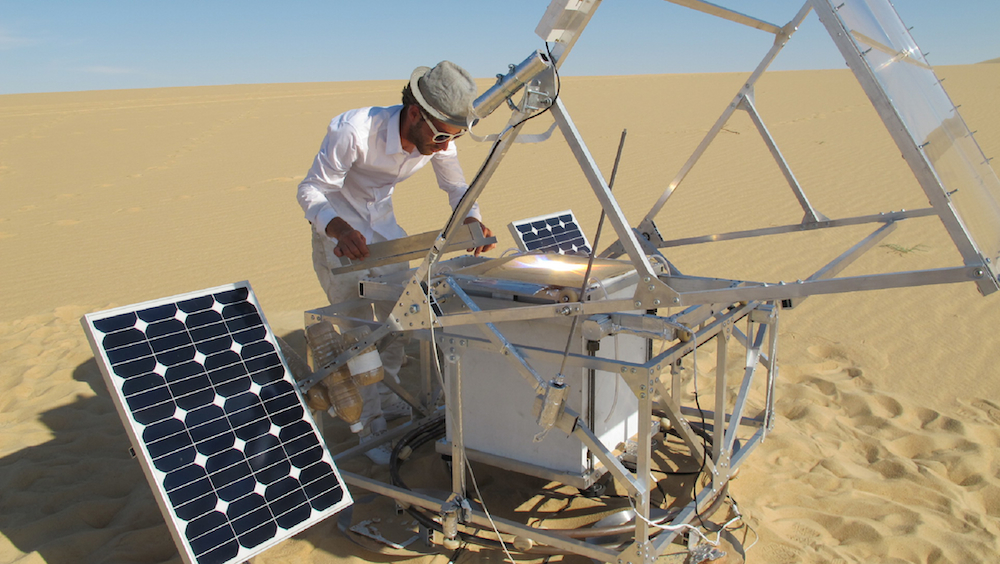

This year, acting on his vision, our intrepid experimenter returned first to the Moroccan desert and then to the Sahara with a new device — the SolarSinter. Using the sun's rays rather than a laser, the fully automated device heats selective portions of silica sand to the melting point. It continuously sweeps and melts new layers of fresh sand to build up a 3D object. Also, the SolarSinter moves automatically to keep the sun in optimum focus.

The machine is driven by ReplicatorG, an open source 3D printing program that is used to drive such popular machines as MakerBot, Thing-O-Matic, and the RepRap machine we discussed in an earlier blog.

On his website, here's how Kayser describes what he's up to: "This process of converting a powdery substance via a heating process into a solid form is known as sintering and has in recent years become a central process in design prototyping known as 3D printing or SLS (selective laser sintering). These 3D printers use laser technology to create very precise 3D objects from a variety of powdered plastics, resins and metals — the objects being the exact physical counterparts of the computer-drawn 3D designs inputted by the designer. By using the sun's rays instead of a laser and sand instead of resins, I had the basis of an entirely new solar-powered machine and production process for making glass objects that taps into the abundant supplies of sun and sand to be found in the deserts of the world."

The rather surrealistic video on the website (it has a somewhat Einstein on the Beach quality to it) shows Kayser setting up the machine and then running it to produce a strangely contorted glass object and a rough-hewn glass bowl.

You'll notice that he shields himself from the scorching sun by wearing a dapper hat, sunglasses and all white clothing.

Kayser may be an Englishman, but he's nobody's fool.

Markus Kayser - Solar Sinter Project from Markus Kayser on Vimeo.