National Robotics Initiative Plays Key Role in Broader Manufacturing Strategy

When President Obama visited Carnegie Mellon University in June to launch the Advanced Manufacturing Partnership (AMP), he also declared a new focus on next-generation robotics. Addressing the crowd, Obama joked, "You might not know this, but one of my responsibilities as Commander-in-Chief is to keep an eye on robots. And I'm pleased to report that the robots you manufacture here seem peaceful — at least for now."

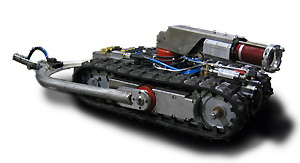

The President had just finished touring CMU's National Robotics Engineering Center, where he witnessed first-hand robotics applications ranging from military uses to sewer inspections. The President was especially impressed with a computer simulation program from Procter & Gamble targeted at smaller manufacturers that normally would not have the resources for such a system. He also made note of the work of RedZone Robotics, which developed a robot to inspect major sewer pipelines.

The President had just finished touring CMU's National Robotics Engineering Center, where he witnessed first-hand robotics applications ranging from military uses to sewer inspections. The President was especially impressed with a computer simulation program from Procter & Gamble targeted at smaller manufacturers that normally would not have the resources for such a system. He also made note of the work of RedZone Robotics, which developed a robot to inspect major sewer pipelines.

During his speech, President Obama stated that "to help everyone from factory workers to astronauts carry out more complicated tasks, NASA and other agencies will support research into next-generation robotics."

He is referring to the National Robotics Initiative, which seeks to boost America's high-tech manufacturing sector by enhancing human capabilities, performance and safety. The initiative includes the cooperation of the National Science Foundation (NSF), the National Aeronautics and Space Administration (NASA), the National Institutes of Health and the Department of Agriculture, which are making $70 million available to support research in next-generation robots.

He is referring to the National Robotics Initiative, which seeks to boost America's high-tech manufacturing sector by enhancing human capabilities, performance and safety. The initiative includes the cooperation of the National Science Foundation (NSF), the National Aeronautics and Space Administration (NASA), the National Institutes of Health and the Department of Agriculture, which are making $70 million available to support research in next-generation robots.

In a related announcement, Helen Greiner, president and CEO of CyPhyWorks, president of the Robotics Technology Consortium, and co-founder of iRobot, stated:

"Investing in robotics is more than just money for research and development, it is a vehicle to transform American lives and revitalize the American economy. Indeed, we are at a critical juncture where we are seeing robotics transition from the laboratory to generate new businesses, create jobs and confront the important challenges facing our nation. The nation's robotics community is collectively poised to advance the technology and at the same time accelerate the transition of these technologies from the lab into the market."

Robotic technology has enabled a host of advancements in fields as diverse as manufacturing, logistics, medicine, healthcare, military, agriculture, and consumer products. Assistive systems and devices are improving the outcomes of medical procedures and shortening hospital stays.

The White House's Office of Science Technology Policy (OSTP) did a terrific job explaining the necessity for the project:

- Robotics can address a broad range of national needs such as advanced manufacturing, logistics, services, transportation, homeland security, defense, medicine, healthcare, space exploration, environmental monitoring, and agriculture.

- Robotics technology is reaching a "tipping point" and is poised for explosive growth because of improvements in core technologies such as microprocessors, sensors, and algorithms.

- Robotics can play an important role in science, technology, engineering and mathematics (STEM) education because it encourages hands-on learning and the integration of science, engineering, and creative thinking.

- Members of the research community such as the Computing Community Consortium and program managers in key sciences have developed a shared vision and an ambitious technical agenda for developing next-generation robotic systems that can safely work with humans and augment human capabilities.

According to the OSTP team, the aim of the initiative is to develop robots that work with or beside people to achieve a best of both worlds approach that includes the following applications:

- Increase the productivity of workers in the manufacturing sector.

- Assist astronauts in dangerous and expensive missions.

- Help scientists accelerate the discovery of new, life-saving drugs.

- Improve food safety by rapidly sensing microbial contamination.

The focus here is on working with people and enhancing their natural abilities. The message might help to ward off claims that robots will replace or otherwise eliminate human jobs. In reality, robots, like the industrial revolution itself, create opportunities and jobs, and support the kind of efficiencies that a global economy demands. Reliance on technology, in general, creates the need for a better-educated workforce, but that's why training is also a big part of any forward-thinking manufacturing strategy.

It's starting to sink in to the American psyche: digital manufacturing is vital to our nation's continued competitiveness. In order to safeguard our economic future and compete in the global marketplace, we need to fundamentally transform the way we make things. Robots can help us do that.