Make Your Own Stuff: RepRap and the Home 3D Printer

The do-it-yourself (DIY) urge has taken a new and unexpected turn. Low cost, desktop 3D printers that use plastics and other materials to print just about anything you want are making their way into the home.

An additive manufacturing technology, the 3D printing of parts from CAD-generated designs has been used to create product prototypes or the end product itself for many years. However, the printers are complex and expensive.

But now the technology is becoming available to anyone with a PC and the open source equivalent of a 3D printer device. RepRap is leading the charge.

Subversive Stuff

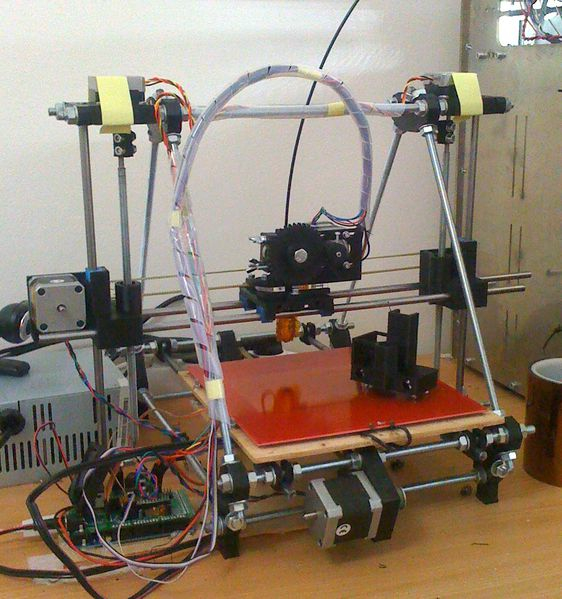

Like many open source movements, RepRap is delightfully subversive. The non-profit organization has created a family of low cost desktop 3D printers capable of printing plastic objects. Specifications for the printers have been released under the GNU General Public License.

These printers aren't just ordinary devices. Because they are made of plastic parts, this is a self-replicating machine — you can print another RepRap and give it to a friend. If you're handy with electromechanical gear and make some enhancements to your printer, you can share your work with other DIY 3D printer fans on the RepRap website.

Once people start printing printers for their friends and family, the stage is set for exponential growth. RepRap and the other open source printers could soon be showing up in homes everywhere. People will be printing everything from wine glasses and mini mugs to back scratchers and hand-held vacuum cleaners. (These are among the many item designs that can be downloaded from the RepRap website.)

For the story behind RepRap, it's worth watching this short video. You can also see more of the amazing capabilities of these 3D printers in a Fab@Home video on You Tube.

Need it? Print it

Consider the implications. The traditional manufacturing supply chain will be upended. Instead of going to a store or ordering online, you can design the object of your desire yourself, or simply download a CAD file from an on-line source and print away. Making the rounds of the Web is a 2008 quote attributed to Chris DiBona, Open Source Programs Manager at Google — "Think of RepRap as a China on your desktop."

Well, not quite. There are issues of quality, design, safety, object size and complexity, warranties, etc. Traditional manufacturing isn't going away anytime soon.

But even so, what a boon for would-be entrepreneurs who have an idea for a new widget that's bound to bring fame and fortune. Just design your dream using a trusty CAD program, rapid prototype it to work out the kinks, print it up, and go straight to eBay. And watch the sales roll in.

It doesn't look like we're going to have to wait until the 24th century to see the equivalent of a Star Trek replicator. RepRaps and their progeny are the precursors of a new breed of devices that someday soon will make a lot of what you want when you want it in the comfort of your home.